Background

How to reduce the amount of CO2 in the atmosphere, the primary cause of global warming, is one of the biggest issues we have to deal with in the 21st century.

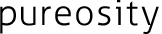

In fact, the transportation section including cars accounts for more than 20% of net CO2 emittance in the world. In that context, so much effort has been made into electric, fuel cell vehicles and so on these days, but most of the cars in the world would be still equipped with engines by 2050 according to IEA. Hence, the energy efficiency of engines must be improved (Fig. 1).

Fig.1 Global portfolio of technologies for passenger LDVs

Fig.1 Global portfolio of technologies for passenger LDVs

(from Energy Technology Perspectives 2012 – International Energy Agency)

Improvement of Energy Efficiency by Lean Burn Technology

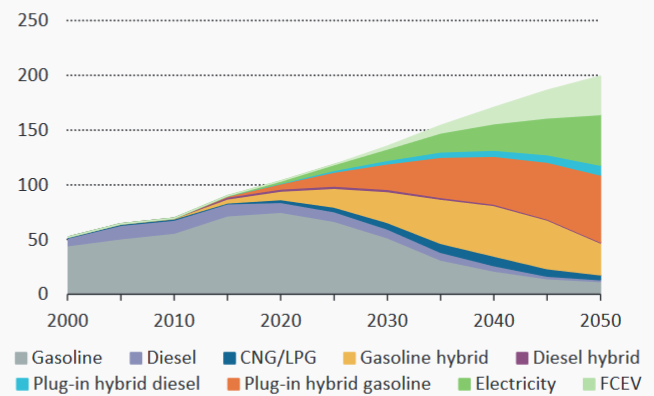

Lean burn technology is a promising technology to improve the energy efficiency. The fuel in lean burn technology system is burnt in the presence of excess air compared to the theoretical air/fuel ratio. The system was initially developed in the 1990s and is proved to improve the efficiency more than 10%. However, the excess amount of feed air leads to higher probability of generating nitrogen oxides, and doesn’t allow the three-way catalyst commonly used in car engines to reduce nitrogen oxides properly. Due to the tighter regulation about nitrogen oxides in the early 2000s, the research and development of lean burn technology has attained great attention (Fig. 2).

Fig.2

Fig.2

Feed Gas Refinery by Gas Separation Membrane

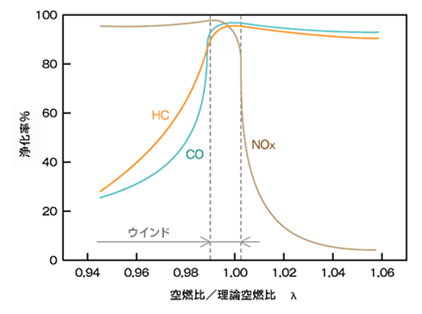

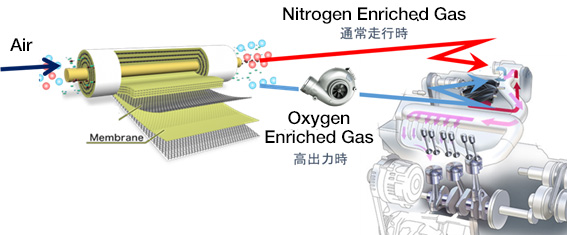

We have been trying to refine the air into nitrogen enriched form by using gas separation membranes so that we can achieve lean burn technology to improve the efficiency, complying with the new regulation under the good collaboration with one of the best car companies (Fig. 3).

Fig.3

Fig.3

Feasible Gas Separation Membrane

Commercially available membranes such as polyimides or polysulfones have a common problem, namely, slow permeance of gases. Such membranes are not feasible in this project whose aim is to deal with large amount of air to provide car engines with the refined gas. Thus, we require a membrane with: 1. Fast permeance of gases, 2. High selectivity in oxygen/nitrogen separation and 3. Thin film configuration in order to achieve our goal.

Our material, TOX-PIM-1, matches the first two conditions, so we are now working on making thinner membranes and scaling them up in order to put them in practical industrial use.

Future Prospects

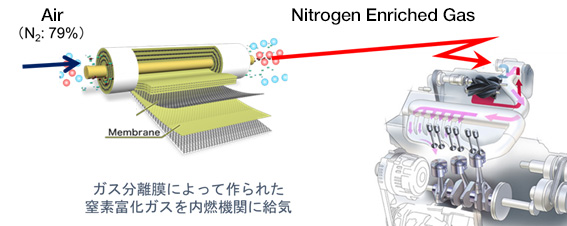

Application of O2/N2 separation membrane to cars’ engines and other vehicles’ is not only limited to the lean burn technology. The selectively separated and stored oxygen enriched air could also be used to boost engines when they need higher output like accelerating or driving on steep slopes. Feeding the enriched oxygen into engines would temporally make it possible to burn more fuel. Combining this concept with lean burn technology, we are expecting to improve the efficiency significantly (Fig. 4).

Fig. 4

Fig. 4