Global Targets / Our Research

Membranes in Food industry

Membrane technology in food processing industry

Food for Hunger

- 00% more food demand for 9 billion people by 2050

- 3.1 million children (under age of 5) died in 2015 (malnutrition and foodborne diseases are the main causes)

Food for Health

- Global market $000.7 billion in 2013

- Annual growth 7.4%

Nutritional food and beverage (leading to enhanced health and disease prevention)

Some demanding functional foods

1) Dairy industry

- The market of global dairy ingredients by 2020 = $ 59.8 billion

- annual growth rate = 5.6%

2) Vegetable/fruit juices industry

- The market of juice concentrates by 2021 = $ 93.94 billion

- annual growth rate = 6%

3) Beverage industry

- The market of sports drink by 2020 = $ 5.6 billion (annual growth rate = 4%)

- The market of alcoholic drink by 2020 = $ 1.8 billion (annual growth rate = 9.6%)

Functional foods and their effect on human life

To generate nutritional foods, food production should be as mild as possible and avoid contamination.

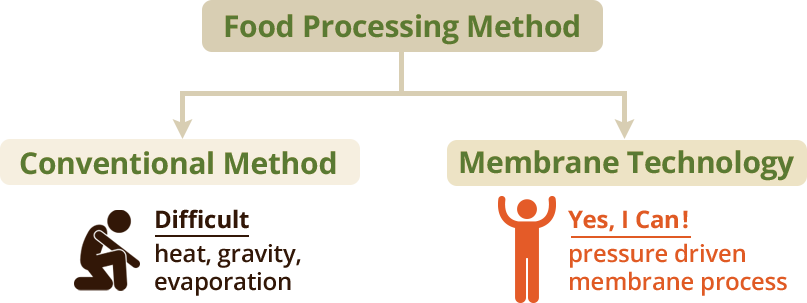

How can we achieve nutritional food products for consumer?

Membrane technology used in building functional food products

- isolate dairy products (whey proteins, fats)

- produce vegetable/fruit juices with high nutrients and control water percentage

- isolate nutrients such as vitamins, amino acids in pure form

- remove bacteria and germs from foods

- control alcohol percentage, salt amount in beverage

Fig: Membrane technologies in the food industry (pressure driven membrane process)

The membrane technology is superior than conventional filtration

- 1. food processing at moderate temperature

- 2. high selectivity based on unique separation mechanisms, for example sieving, solution-diffusion or ion-exchange

- 3. compact and modular design for easy installation and extension

- 4. low energy consumption compared to conventional method